Bi And Tri Pyramidal Structural Hulls

Changing The Shape

Most of the world has unofficially determined that cylindrical and spherical structures best withstand internal or external pressure. The exacting arc tolerances and curved nature of the parts required to construct traditional pressure vessels significantly increase the degree of difficulty and hence the cost of such construction for these structures.

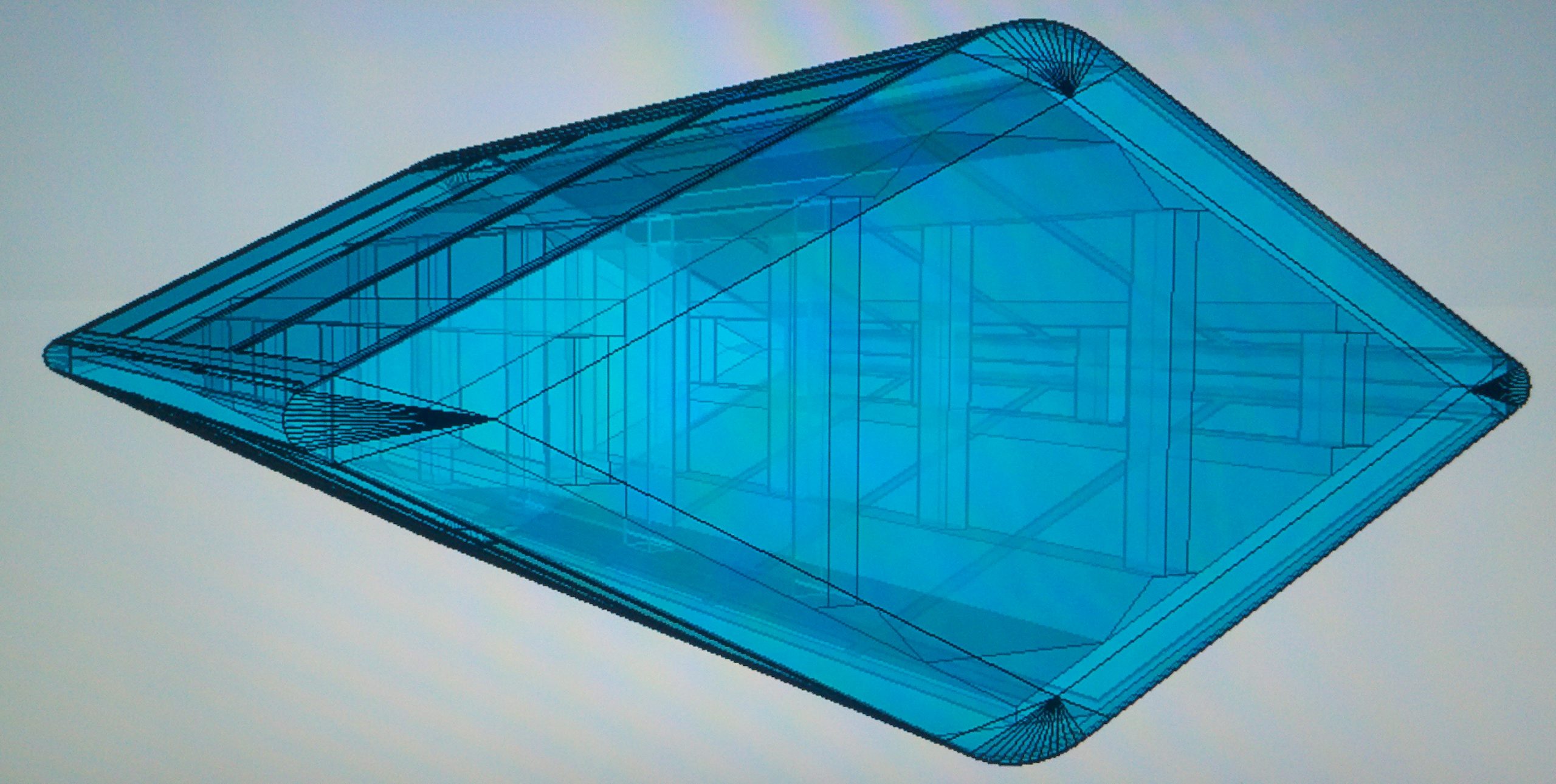

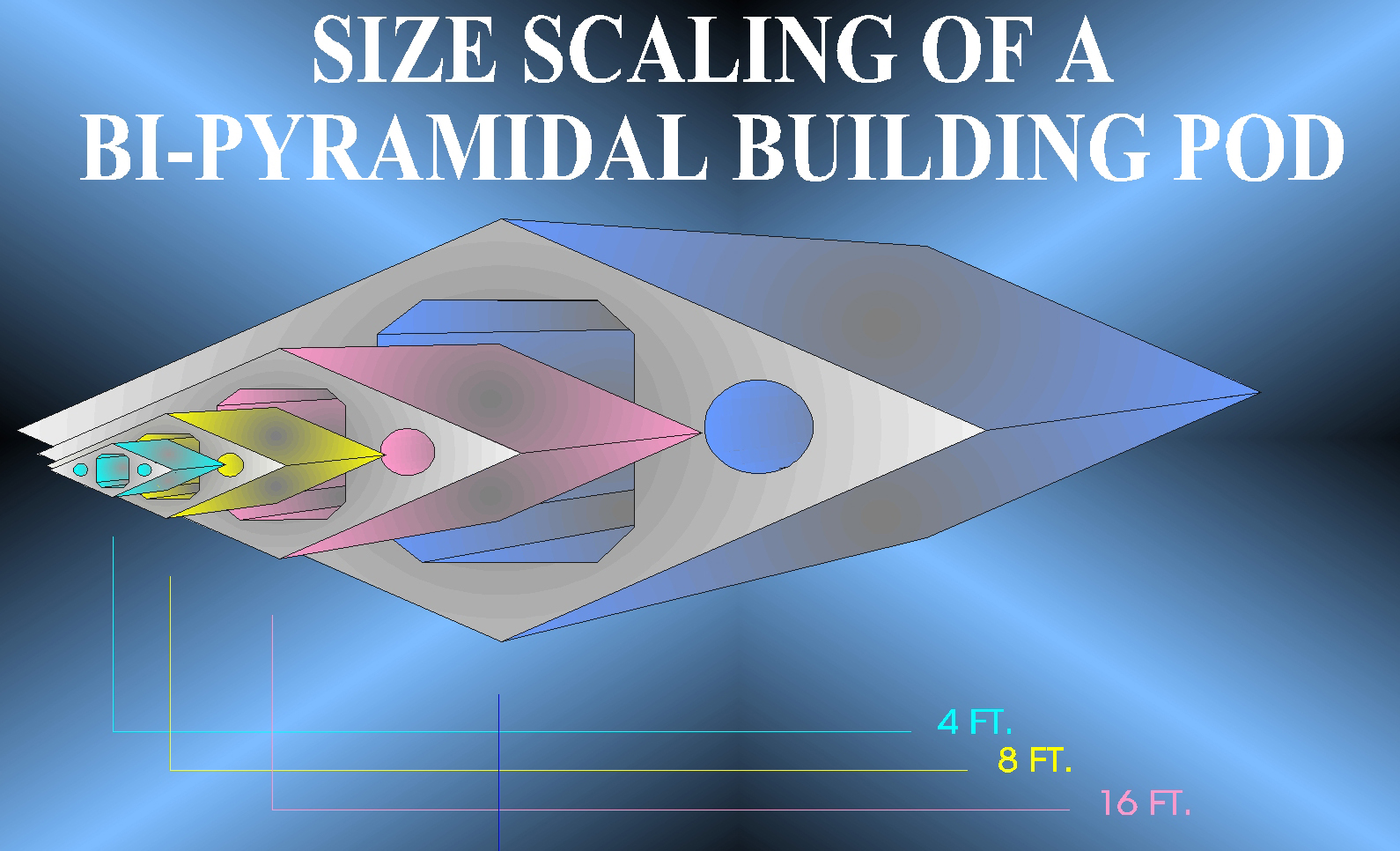

In contrast, Global Oceanic Designs’ Bi- and Tri-Pyramidal Structural Hulls utilize ‘flat stock’ (or non-curved) parts throughout. This revolutionary, yet extremely simple, design difference is the primary advantage of Bi- and Tri-Pyramidal Hulls because it greatly simplifies their construction process when compared to current standards.

The ‘flat stock’ feature of Global Oceanic Designs’ structural hulls has been accurately described as a “manufacturer’s dream.” Furthermore, entirely unlike conventional hull designs, the Bi- and Tri-Pyramidal Structural Hulls are easily scalable and inter-connectable in modular designs.

Structures maintain the same collective strength when scaled up as long as proper ratios are maintained. Connecting individual modules or existing multiple-unit structures can be accomplished using simple techniques ranging from permanent lamination to temporary screws or bolts. This versatility creates almost innumerable forms and countless applications for these structures from small pressure housings to super tankers.

Significant prototype testing of two Tri-Pyramidal Hulls and one Bi-Pyramidal Hull conducted by Southwest Research Institute (SwRI) confirmed the extraordinary capabilities of these hulls to withstand hydrostatic pressure.

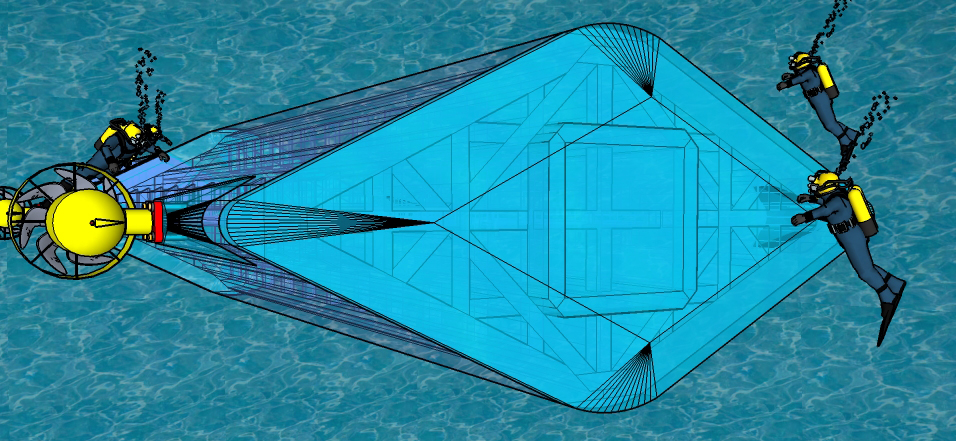

It is important to understand that Bi- and Tri-Pyramidal Structural Hulls do not require environments involving significant internal or external pressures to be commercially-viable technologies.

Thinner materials could be used to create a structure that provides safe housing to its inhabitants through any natural disaster on land or over the water. The structures allow the use of thinner, flat-stock building materials to adapt the structure to the rigors of the environment around it. The fast, simple construction of the buildings also allows for the rapid deployment of shelters before or after an incident occurs, and the ability to combine in mass scale to accelerate the construction of entire cities.

This adaptation reaches all the way into outer space where private companies currently competing in a second space race are spending hundreds of millions of dollars in pursuit of the infrastructure necessary to bring commercial space travel into existence. These groups are looking for light-weight, densely-packed structures that are strong enough to withstand the rigors of outer space. The modularity and ease of construction when compared to conventional space structures place the Bi- and Tri- Pyramid Hull light years ahead of this exploding industry!

Structural Hull Testing

The Bi- and Tri-Pyramidal Structural Hulls have been hydrostatically pressure tested and proven by the Southwest Research Institute in San Antonio, Texas.

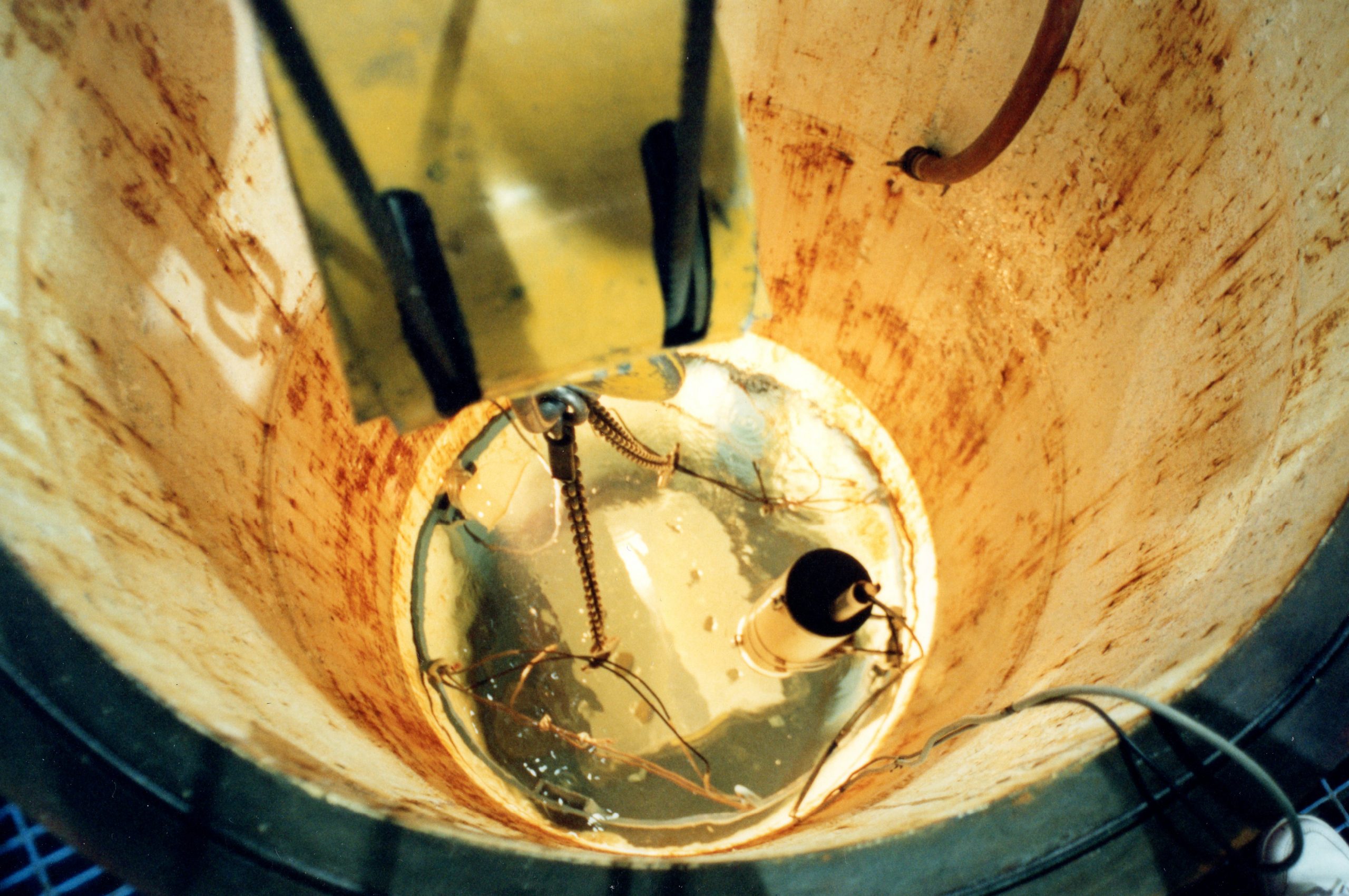

Southwest Research Institute (SwRI) was commissioned to test and study the ability of these prototypes to withstand external pressure in their sophisticated Ocean Simulation Laboratory. SwRI is world renowned as one of the top applied research and development organizations in the United States and has considerable resources including over two million square feet of test facilities, laboratories, workshops and offices. The institute is composed of eleven technical divisions that offer a wide range of expertise and services to various industries and governmental groups.

Global’s Mosquito Hawk I was the first to be tested by Southwest Research Institute in the Ocean Simulation Laboratory.

The Mosquito Hawk I represents the first prototype of the Tri-Pyramidal Structural Hull and is constructed entirely of 3/4 inch thick, poplar wood plank that is simply laminated and glued together without any nuts, bolts, or screws of any kind.

Before being placed in the pressure vessel for the test, the SwRI engineers measured and weighed the Mosquito Hawk I for data points to calculate the theoretical depth in water at which the structure would fail. They determined that the structure would fail at or before 98 feet of depth as represented by 42 psig in the pressure vessel. Kenneth W. Welch Jr., Global Oceanic Designs’ Chief Inventor, contended that the Mosquito Hawk I would reach at least 387 feet of depth represented by 167 psig. The stark contrast between these predictions put Mr. Welch’s universal ratio methodology that created the structures to the test. Only exceeding 387 feet would be considered a success.

Finally, the testing on the Mosquito Hawk I commenced. The structure was inserted into the pressure vessel, and the Ocean Simulation Laboratory staff steadily injected more water to increase pressure and simulate depth.

All eyes focused on the external digital readout of the pressure being withstood by the first Tri-Pyramidal Structural Hull. The sophisticated monitoring equipment detected no sounds or changes in the structure as the gauge showed a hydrostatic pressure equivalent to 250 feet of depth in fresh water. The SwRI engineers hypothesized that the hull suffered a pinhole breach early in the dive that allowed water to fill the hull without it ever registering as a failure of the structure.

The group determined that the best course of action would be to remove Mosquito Hawk I to examine it. When removed from the tank, no water drained to indicate the location of a breach. In fact, the hull weighed exactly what it had before the test.

Everyone present excitedly agreed to resume the testing after recalibration and verification of the accuracy of the instrumentation being used. After successfully completing a simulated underwater dive of more than 250% of the experts’ hypothesis, Mosquito Hawk I was already on its second simulated dive.

The process was repeated, and the hull showed no signs of weakness as the pressure passed the 250 foot depth simulation again. In fact, the pressure in the tank reached 167 psig which corresponds to Mr. Welch’s prediction of the Mosquito Hawk I withstanding the pressure of 387 feet of depth in fresh water.

Many of the SwRI participants were still skeptical, so the tank was depressurized to inspect the hull and recalibrate instruments. Again, the hull showed absolutely no sign of damage.

Now that the Structure had reached Mr. Welch’s targeted depth nearly 300% beyond SwRI’s theoretical maximum, the Mosquito Hawk I would be taken to crush depth on the third dive to determine an actual maximum external pressure for the Hull.

Soon the simulated depth of 387 feet was reached for a second time that afternoon in a third dive that converted many of the skeptics into believers. The ever-increasing hydrostatic pressure eventually overcame the Structure at 172 psig for a simulated depth of 398 feet of fresh water, and the Mosquito Hawk I became the deepest-diving wooden submersible in history.

At this point, Mr. Welch knew that he had discovered a scientific phenomenon. The wooden Tri-Pyramidal Structural Hull exceeded the experts’ theoretical maximum depth by 300 feet and confirmed that his vision of a universal ratio mathematical system was worthy of further research and funding.

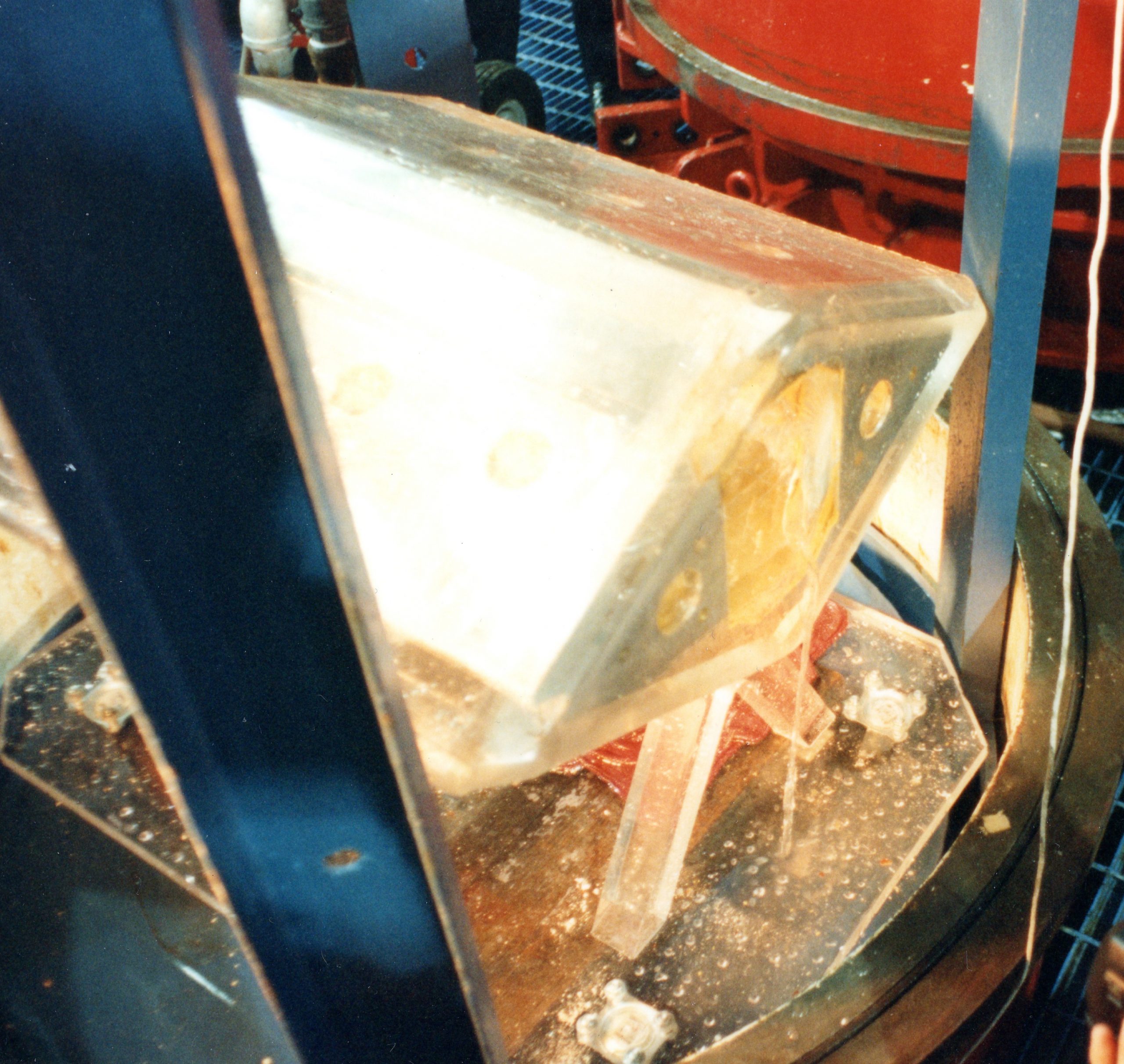

Mr. Welch and his team returned to Southwest Research Institute to test a second version of its Tri-Pyramidal Structural Hull. The Crystal Quest I is a “double-long” Tri-Pyramidal Hull constructed entirely of one-inch-thick, clear acrylic. Like the Mosquito Hawk, its components were simply laminated and glued together rather than the use of any nuts, bolts, or screws.

Crystal Quest I was equipped with batteries, lights, a camera, and a full robotics package that could be controlled via infrared commands. In fact, it functioned as an operational Autonomous Underwater Vehicle (AUV). In addition to these components, Global was excited to test the structure’s ability to withstand hydro-static pressure in the “double-long” configurations of the Tri-Pyramidal Hull.

The testing process was performed in the same manner as the verification of the Mosquito Hawk I, and Crystal Quest I performed beautifully. Again, the SwRI engineers predicted a simulated depth of 486 feet as Mr. Welch insisted on 1,765 feet. The structure was overwhelmed by the hydro-static pressure at 1,803 feet.

The second successful test exactly confirmed the universal ratio math for a second time. The theoretical maximum depth that Crystal Quest I would be able to withstand was calculated using the same methodology and hypothesized to be exactly half of that of the singular unit. Also, the test confirmed the ability to use components within the structure which will prove invaluable to underwater industry.

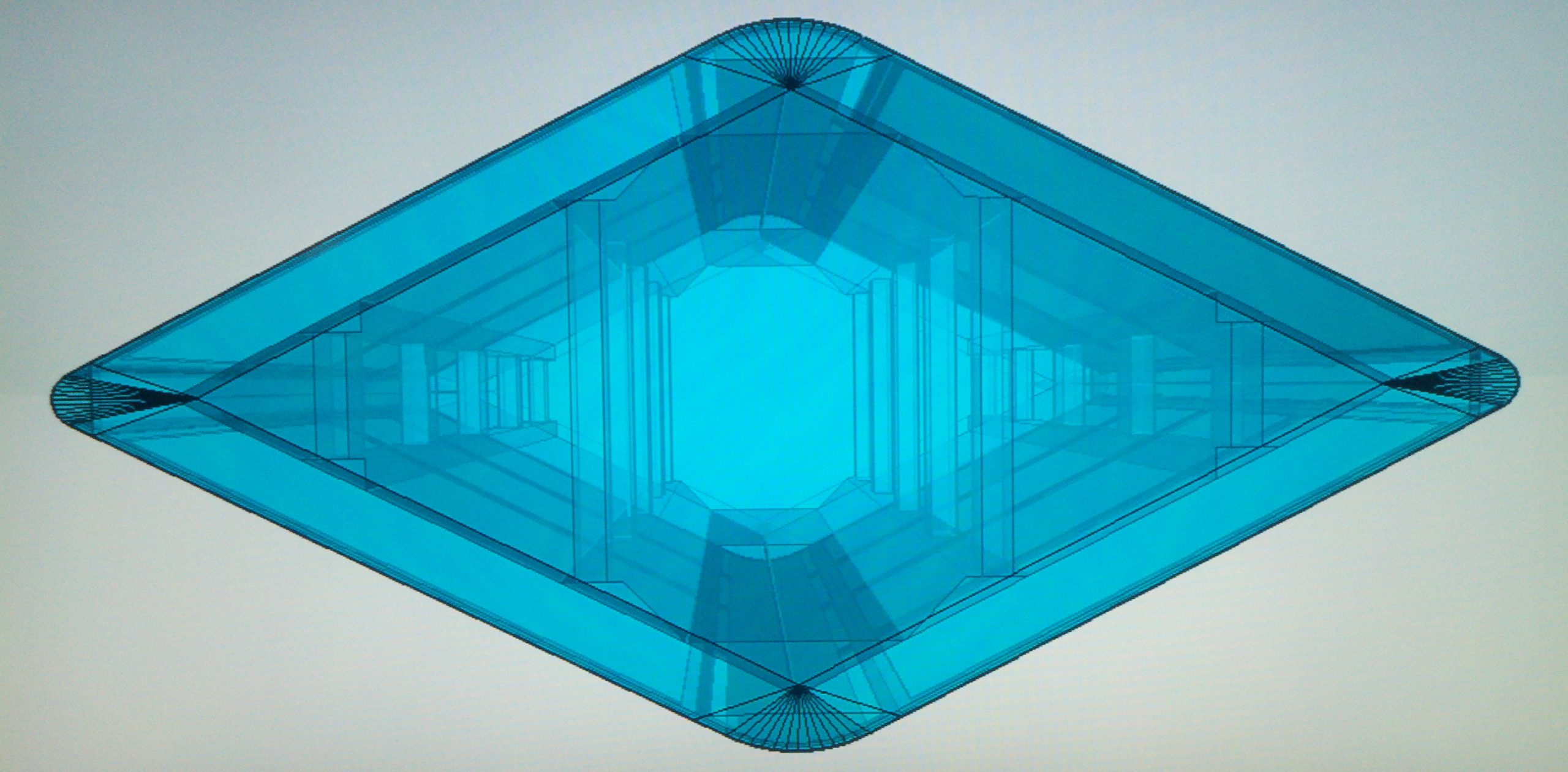

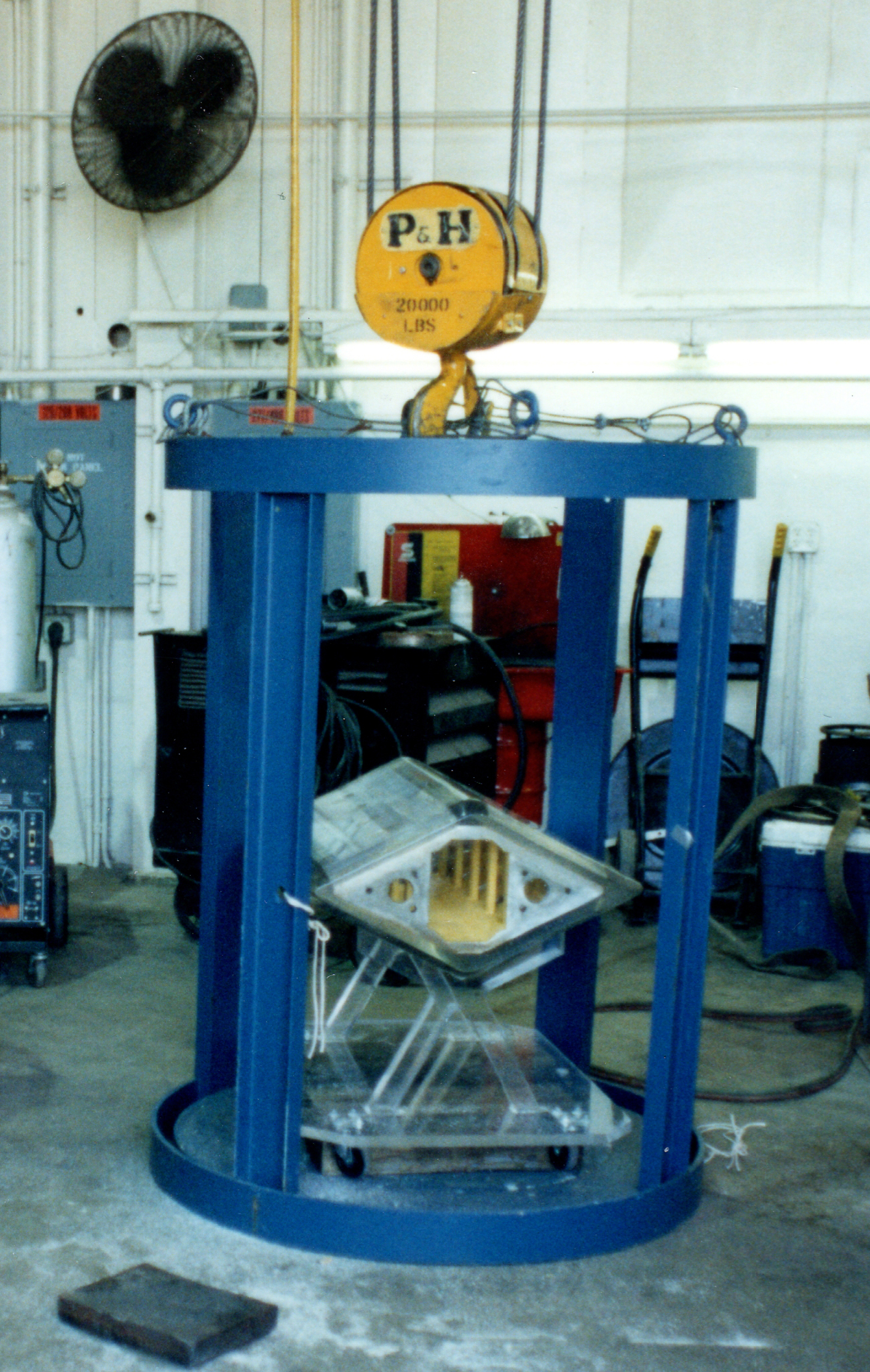

When it was time to return to Southwest Research Institute’s Ocean Simulation Laboratory with a third prototype for testing, Crystal Quest II was met with anticipation. The ability to build a Bi-Pyramidal Structural Hull out of multiple different materials was next to be observed.

The Hull has an interior skeleton of one-half-inch thick steel that is encased by 1 ½-inch-thick acrylic plate.

The internal steel components were welded together, and the acrylic plating was secured using lamination to continue to avoid the cost and complications of nuts, bolts, and screws.

The completed Crystal Quest II underwent hydrostatic pressure testing at Southwest Research Institute in the same manner as the previous Structural Models. After exceeding the experts’ calculations by over 300% again, the structure failed at 1,641 psig which represents 3,750 feet of depth in freshwater, and Crystal Quest II is recorded as the deepest-diving, non-spherical submersible in history.

The series of tests performed by the Ocean Simulation Laboratory at Southwest Research Institute on the Bi-Pyramidal and Tri-Pyramidal Hulls verifies their ability to withstand external pressure as well as the universal ratio methodology used to create them. The Structures not only exceeded all conventional expectations, but also have proven to have calculable, repeatable performance characteristics.

The knowledge gained through these experiments and verification has paved the way for further designs that are now available to the world for successful development under our oceans, on and above our lakes and rivers and in outer space.