X-Wave Facility

X-Wave Facility

Extreme Wave-Tank Testing

Texas’ Ultimate Simulated Wave Research Laboratory

Global Oceanic Designs, Inc. (Global) is proud to introduce its recently acquired and renovated state of the art 7.6 acre site, including showcase building and large wave pool complex, known as Global’s X-WAVE Facility (X-WAVE). The first of its kind, X-WAVE provides a chemical-free fresh water environment suited to demonstrate wave motion and wave properties. X-WAVE was specifically designed to facilitate underwater and sea-surface technologies testing and conduct ocean related research, development and training. It facilitates a controlled and adaptable environment for projects such as underwater and sea-surface construction research, vessel testing, wave energy research and future ocean related research and development.

The wave and ocean power industry is evolving and X-WAVE has the capacity to house a diverse range of water related systems to conduct studies and research. X-WAVE capabilities to recreate/simulate sea dynamics offers a site to test and refine marine systems of various arrangements. Testing in water tanks accelerate research completion time facilitating researchers and inventors to bring clean wave-energy products to market faster, more cost-effectively, and at a lower risk. X-WAVE also serves as a facility for community driven activities such as dive training, rescue team exercises and an educational showcase for local schools and universities, among others.

Conveniently located on the same street, only a short 2-minute drive from Global’s headquarters in Willis, Texas, X-WAVE sits on a newly renovated, 7.6 acre property valued at $3.6 million including building, well, roadways, freshwater tower, fencing, pool complex and Tri-Pyramidal wave system.

As visitors approach the property, they drive through the blue gates and are immediately greeted by the immense wave pool complex and its adjacent buildings. Visitors and clients are directed on a paved driveway that facilitates a parking area in front of the large red showcase metal building.

The X-WAVE building sits towards the front right side of the property. It is surrounded by green landscaped areas and a white rock road that circles around the pool’s perimeter.

Access to the pool’s deck is provided by means of two metal, industrial grade staircases located on each side of the pool.

The X-WAVE pool and other buildings occupy approximately 3.6 acres of land. The remaining 4 acres of the property, although still undeveloped, are clear of wild brush and populated with tall native trees. The entire property was recently secured by the installation of an 8 ft. tall, galvanized chain-link fence surrounding its grounds.

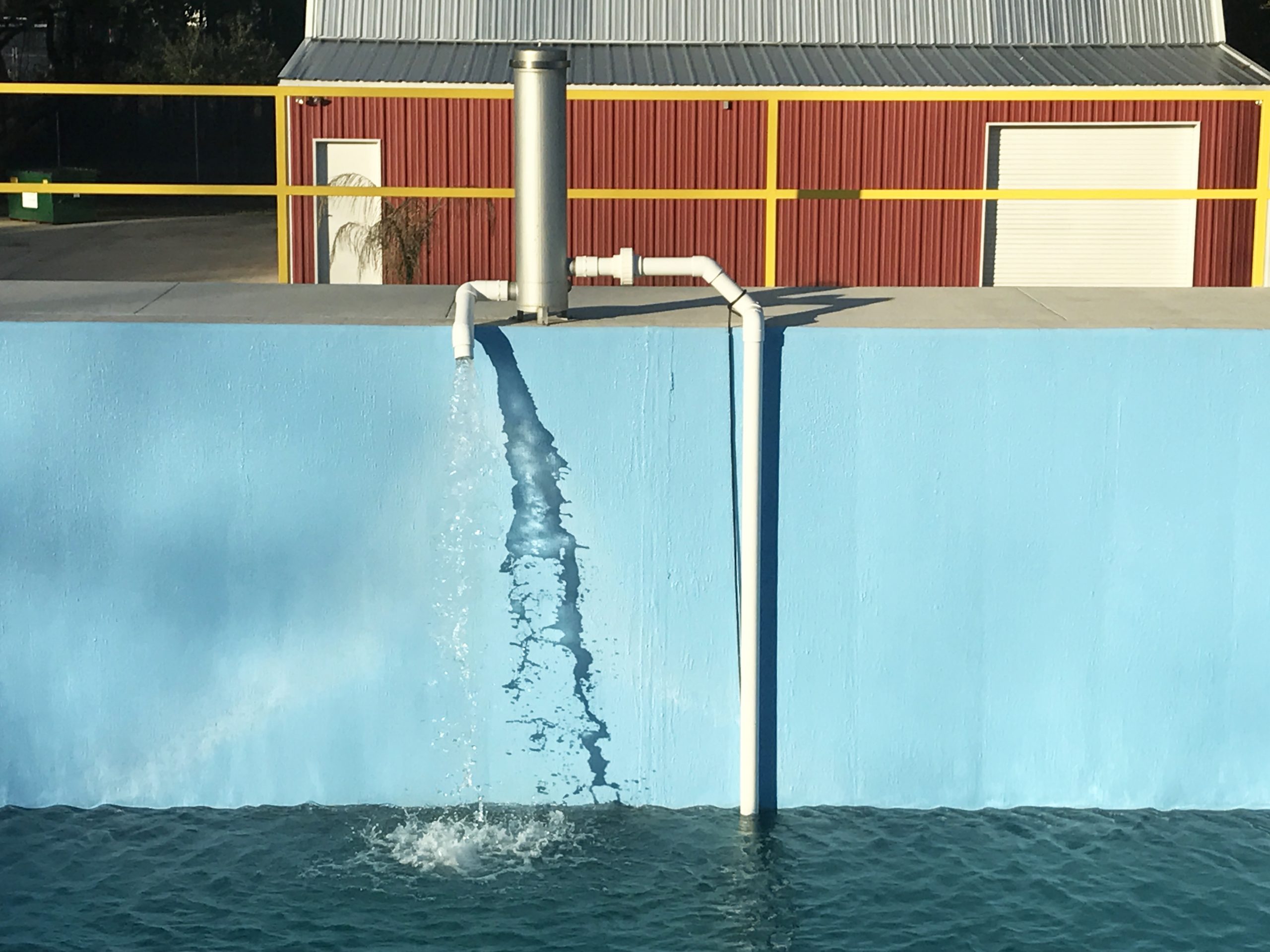

The $940,000 wave pool complex, includes a wave pool that measures 150 ft. long, 40 ft. wide, it has a standard operational depth of 8 ft. and a maximum depth capability of 16 ft.. X-WAVE is capable of simulating ocean-like waves ranging from 6 inches to a projected maximum wave height of 7 feet.

The flexibility of the wave size can accommodate a large number of testing requirements, currently the X-WAVE pool is in the process of testing SeaDog Systems, Inc. Wave Energy Pumps; made possible by a recently acquired $300,000 research service contract with Global for testing of its new wave energy technology.

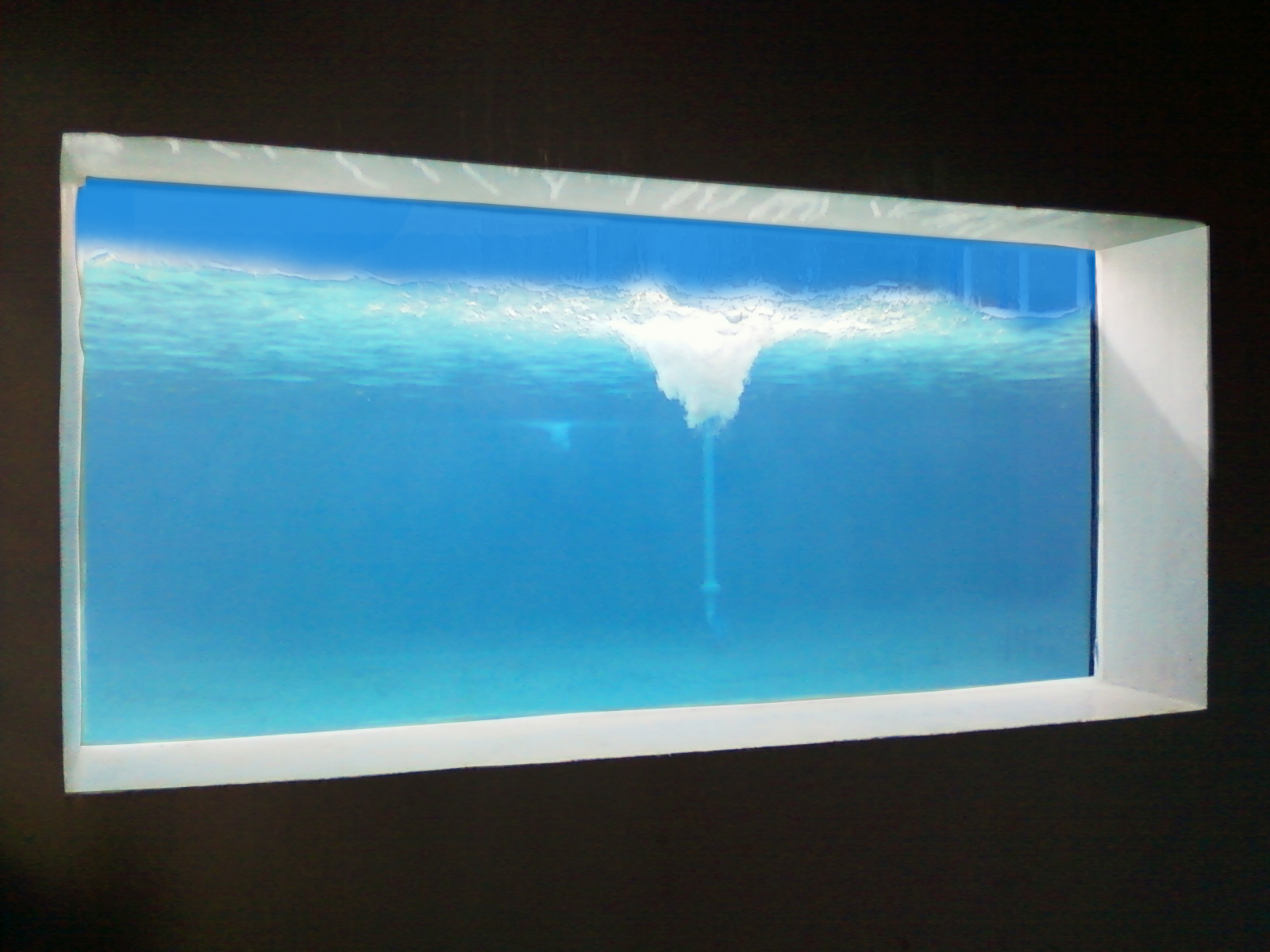

The cutting-edge wave pool is surrounded by various testing and research laboratory facilities. The wave pool is complemented by four adjacent buildings/spaces. There are two underground large rooms located at each end of the wave pool, each room features two underwater viewing ports into the pool.

The clear acrylic viewing ports are 4 ft. high by 8 ft. long and 3 in. thick. Two ports allow a direct view of the wave making systems and the other two ports enable viewing of activities occurring at the far end of the pool. The underground spaces can also be used as investigation and study laboratory areas while testing is taking place in the pool.

The $975,000 Tri-Pyramidal wave making machine (Fulcrum Pond Pounders) is Global’s own proprietary invention. The Fulcrum wave machine is a sophisticated and revolutionary wave making system.

It incorporates the use of magnetic forces combined with a fulcrum to produce mechanical work more efficiently. This innovation enables higher efficiency with less electrical power consumption, maintaining a high performance rate.

There are two additional working spaces located above ground and adjacent to each end of the pool’s edge. One of the spaces is located at the east end of the pool’s deck, it currently serves as a workshop area and in the future it will store a variety of tools and mounting brackets to provide X-WAVE’s clients the ability to modify their testing set ups, repairs, etc.

All the pool maintenance and cleaning equipment is also stored in this room, including an ultramodern, pool cleaning robot that is used to clean the pool’s floor.

This room also stores the high efficiency, 5-micron filters used at each of the four freestanding, high capacity, filtration pump units, located along the edge of the pool (two on each side).

It is worth mentioning that this high-end filtration system brings the water state in the pool to drinkable levels and enables the crystal clear water to be maintained totally chemical-free.

The other above-ground space is the facility’s control room, it is located at the west end of the pool’s deck. This room accommodates Global’s most up-to-date control, monitoring, data collecting and data analyzing equipment. It also contains the recently installed 3-phase electrical disconnect box that powers X-WAVE’s new $180,000, state-of-the-art, screw-driven, linear, electrical actuators system.

This system was custom designed to meet the specific operational demands and functions of the Tri-Pyramidal fulcrum, wave makers and their actuator framework.

This system will be controlled by a modern, highly sophisticated computerized touch-screen control panel that also monitors all other inputs and outputs of the entire system; such as flow rates, flow direction, pressures and kilowatts used and/or produced. Most importantly, this newly developed system will be capable of driving and sustaining wave regimes from as low as 6 in. to as high as 7 ft.

In the near future, the control room will house custom designed acrylic tables, chairs, sofas and other upscale décor items.

Cameras, sensors and flat screen monitors will allow observation of all activities in the X-WAVE pool. In combination, this will create an extremely attractive, very comfortable and fully functional work-space from which Global’s current and future clients will be able to take advantage of everything the new X-WAVE pool facility has to offer.

Located across from the wave pool complex, the newly renovated 2,500 sq. ft. metal building serves as a contemporary showcase space for technologies and houses a multi-use office space.

In the near future, Global plans to continue remodeling this building by adding a loft area which will provide a meeting and presentation space, additional office space and restrooms.

Directly behind the metal building is X-WAVE’s water well house. The 389 ft. deep well was drilled into one of Texas’ largest aquifers. Although currently permitted for only 2 million gallons per year, the well is capable of providing a flow rate of about 45 gallons per minute on demand, 24 hours a day, year round. The well’s maximum production capacity is approximately 23.6 million gallons of fresh water per year.

This water flow capability provides a great opportunity for the company. Global is actively considering the construction and development of a small water-bottling plant, creating a potential multi-million-dollar revenue stream. This plant could also become a water-processes site to promote learning and education by offering tours.

The 65 ft. tall, 30,000-gallon capacity water tower on X-WAVE’s property can be connected to a pump system that extracts drinkable fresh water directly from the wave pool. The water tower is an important asset for the development of a drinking water-bottling plant.

After completion of its two-year research service contract with SeaDog Systems, Inc., Global has expansive future plans for the X-WAVE pool facility.

As of late January 2017, Global is moving forward in exercising its option to purchase with a local bank to acquire the X-WAVE property, two years ahead of the expiration of its three-year lease-with-option-to-purchase. This will make Global the sole owner of the X-WAVE pool property, its facilities and equipment. (This property has been purchased and is now fully owned by Global Oceanic Designs, Inc.)

From the very beginning, a unique wave pool was an integral part of Global’s future development plans. The company envisioned the construction of a X-WAVE like wave pool on its own 5 acre property. Having access to such a wave pool would facilitate and speed the development of several of Global’s water based technologies.

Global could quickly, easily and cost effectively perform hydrodynamic characteristic testing of prototypes built to scale. Successful development of Global’s Bi- and Tri-Pyramidal Structural Hulls, Fulcrum Wave Machine and Hydro technologies, would benefit from easy access to a wave pool.

In late February of 2016, Global became aware that just two blocks away, an abandoned property that featured an existing “alternative energy wave pond” was to be sold at auction at the Montgomery County courthouse.

In early March, this abandoned property was purchased at auction by an investment trust and Global immediately negotiated a lease-with-option-to-purchase contract with the trust. This move aligned extremely well with Global’s future expansion plans by eliminating the need for the construction of a wave pool on its current property for prototype testing, as it had originally intended.

One week after the property auction, the abandoned furniture, tools, equipment, etc. were sold at auction on the property and Global attended that sale and purchased all items it deemed useful to the operation and maintenance of the wave pool and laboratory facilities.

Realizing that the property had been abandoned and completely neglected for almost five years, Global spent a thirty-day period to perform detailed and extensive inspections into every aspect of the property.

The wave pool, red metal building, elevated water tower, well house and water well had all suffered varying degrees of degradation and deterioration from years of neglect. Restoration work bids were solicited and collected from numerous contractors in order to determine repair and upgrade costs.

After extensive investigation and deliberation, Global’s Board of Directors authorized the expenditure of $385,000 to renovate existing structures, upgrade equipment and bring the entire facility on-line in first-class form to suit Global’s purposes.

The lease-option-to-purchase contract between Global and the investment trust was signed on April 21, 2016 and authorized Global to take possession of the property for a period of three years. With a signed contract, Global was ready to begin the extensive, nearly one-year process of rehabilitating, improving the property and upgrading the wave pool and its associated buildings and equipment.

Global and SeaDog Systems signed a Collaboration Agreement in April 2016 that grants SeaDog Systems a 24-month exclusive access to the X-WAVE facility. In the collaboration agreement, Global agreed to rehabilitate and upgrade the property, buildings and pool complex and provide consulting expertise in testing, refining and commercializing SeaDog System’s wave technology products. It was also agreed that SeaDog Systems would participate in the substantial improvements to the operation of the Tri-Pyramidal wave makers to provide much larger waves in order to test its pumps and continue testing SeaDog System’s future technologies at the X-WAVE pool complex.

As of late January 2016, after thousands of man hours, the restoration and upgrade of the property, buildings and X-WAVE pool complex are almost complete, the following is a brief description of that work.

The property was covered with five years of undesirable vegetative growth that had invaded all the lawn and gravel drive areas at the front of the property.

The first step of the renovation was to cut and completely remove all the wild vegetation so that detailed lawn and landscape maintenance could be performed.

Additionally, the trees throughout the entire property had their limbs removed to a height of 16 ft., creating an unobstructed view and clearance for walking the entire grounds.

The cement driveways and parking areas between the street and red metal building were cleared of any overgrown vegetation and thoroughly cleaned and power washed.

Two, one hundred horsepower, hydro-axe machines spent three days mulching the extremely thick tangle of undesirable vegetation, brush, vines and small trees that covered the back undeveloped area of the property.

The hydro-axes mulched everything up to 6 in. diameter or smaller and a ten-man crew spent several days clearing the remaining trees and collecting the resultant debris.

That activity led to the creation of more than forty large brush piles that were then consolidated into much larger piles and burned in open areas.

After conducting a survey and clearing the back acreage, a five to seven man crew spent close to three weeks installing almost one half mile of 8 ft. tall, galvanized chain-link fencing along the north, east and south sides of the property.

Upon inspection, it was determined that the entire roof and all the ceiling insulation of the red metal building, had passed its useful life and needed to be removed and replaced and that the exterior of the building needed to be power washed, scraped and painted with two coats of an industrial coating. Upgraded exterior lighting was also installed at this time. A nine-man crew spent three days to accomplish this task.

In the interior of the building, all four walls were finished with a combination of insulation and sheetrock creating a first-class showcase and office space.

All mechanical equipment and defective air conditioning units were also replaced. In the near future, Global will complete the remodeling of the interior by adding a restroom, small kitchen area and loft, this will add more usable square footage and increase the functionality of the building.

The well house restoration work included power washing the exterior of the building and the repair of all interior sheetrock. The entire building and its interior were painted as well. Upgraded high-quality, exterior lighting was also added.

The 389 ft. deep water well and pump were thoroughly flushed, inspected and repaired as required. Both are now in optimal operational condition and capable of providing a flow rate of approximately 45 gallons per minute. At that rate, this well is capable of producing over 23.6 million gallons per year and the permit limit can be raised.

Global then proceeded to rent an articulating-arm man lift to power wash and clean the 65 ft. tall, 30,000-gallon water tower. All rust was scraped and sanded to bare metal, primed and repainted with industrial grade marine paint.

The water tank is currently in excellent operational condition; it is also worth noting that the stanchions that currently support the 30,000-gallon tank, were originally designed to support up to a 100,000-gallon tank, providing an opportunity for expansion.

Hundreds of man-hours were spent renovating and improving the wave pool building. First, over half a million gallons of stagnant water had to be removed and a thick layer of aquatic slime had to be power washed, hand scraped and scrubbed from the walls.

Over 300 plus, 50-gallon trash bags of slime and sludge had to be shoveled up and removed from the floor.

Once clean, all cracks in the pool walls and floor were treated and filled and the entire 12,080 sq. ft. surface of interior walls and floor received two full coats of Zeron, a two-part, semi-gloss, high-grade, pool epoxy.

That process took 120 gallons of epoxy at a cost of $100 per gallon.

The Tri-Pyramidal wave makers (Fulcrum Pond Pounders) at the west end of the wave pool, the three SeaDog Pumps in the middle of the wave pool and all the cable tie-down plates each got the same power washing, hand scraping, and detailed cleaning treatment.

Exhaustive safety and usability inspections were performed, the results indicated that all of the equipment in the wave pool was sound and only required cosmetic attention.

Rusted areas were hand scraped and sanded to bare metal and all of the equipment received a complete application of primer and two new coats of marine-grade, two-part, acrylithane coating (marine-grade paint), putting them back in showroom state.

After the extensive interior restoration process was complete, the X-WAVE pool was filled to a depth of 8 ft. from the property’s well.

The entire exterior of the wave pool received two coats of marine-grade paint and the two existing wooden stairways were replaced with industrial grade metal stairways.

The new stairways and over 900 ft. of existing handrails around the deck perimeter, received a complete application of primer and two new coats of marine-grade Acrylithane coating.

All cracks around the wave pool’s deck were properly sealed and then stained with high foot-traffic paint. The four, freestanding, 50-gallon per minute, industrial-grade, 5-micron water filters on the deck were cleaned, inspected, and had their pumps replaced.

The below-ground viewing bunkers located at each end of the wave tank were pumped dry, thoroughly power washed, hand-cleaned, caulked and painted.

The interior of the observation room on the far side of the wave-pool was thoroughly cleaned and now serves as a maintenance facility and store room. The exterior was power washed, caulked and painted and upgraded exterior lighting was installed at this time.

Redundant 400 amp, 3-phase electrical service was installed as required to power the new electrical actuators’ motors. This process required trenching from the meter pole across the crushed limestone drive to deliver the electrical conduit to the west end of the X-WAVE pool.

A core drill was used to drill nine, 2 in. diameter holes through the bunker walls and ceiling. Four of those holes were over 16 in. long through hardened waterproof concrete and involved cutting through 3/4 in. rebar.

The interior of the control room on the near side of the wave pool was thoroughly cleaned, painted and new carpet and tile were installed. It also houses the 3-phase electrical disconnect box that supplies power to the actuator system.

The newly upgraded actuator system will replace the original air driven actuator system, which was very difficult to control and only capable of sustaining 3-1/2 ft. waves. The exterior of this control room was power washed, caulked and painted and upgraded exterior lighting was also installed at this time.

The rotten wooden doors at each of the three small bunkers below the wave makers, on the west end of the wave pool were removed. New wooden framing and new metal doors were installed, weather-sealed and painted.

Global Oceanic Designs’ $385,000 investment in the X-WAVE pool facility will open new opportunities for further development of Global’s current and future underwater and sea-surface technologies while creating ample revenue opportunities.

It also creates an elegant research and testing platform for engineers, inventors and entrepreneurs to continue breaking barriers in industries such as vessel testing, underwater construction, infrastructure systems, clean-wave energy and sustainable power alternatives. X-WAVE will serve as a fundamental testing site, providing the means to bring new technologies from concept to market in a fast and viable approach.